.jpg)

.jpg)

.jpg)

.jpg)

| Lifting Capacity | 0.5 ton to 50 ton |

| Lifting Height | 3 m to 30m |

| Lifting Speed | 0.25-21,Single or Dual Speed |

| Working Class | M3, M4, M5 |

| Application | Electric trolley type electric wire rope hoist is widely used in moulds, machinery manufacturing, warehousing logistics, shipbuilding, bridge construction and other industries, factories and other special uses. |

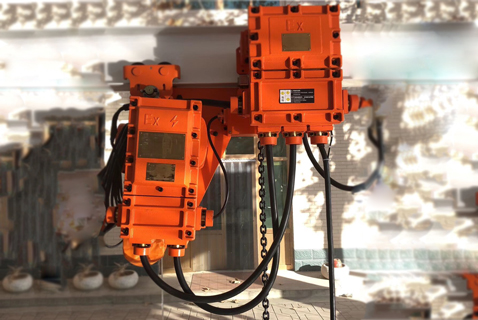

The electric chain hoist consists of motor, transmission mechanism and sprocket. Electric chain hoists are all produced in accordance with international standards. The body has a beautiful appearance, strong and durable. The internal gears are all quenched at high temperature, which increases the wear resistance and toughness of the gears.

Adopting the most advanced technology in the world, fine workmanship, and tight fit between gears.

| Electric Trolley Type Electric Chain Hoist | ||

| Working Class | M3~M5 | |

| Capacity | t | 0.5~50 |

| Lifting Height | m | 3~30 |

| Lifting Speed | m/min | 0.25-21,Single or Dual Speed |

| Travelling Speed | m/min | 11~21,Single or Dual Speed |

| Power Supply | 380V 50HZ 3Phase or Customized | |

| Temperature | ℃ | -20~60 |

| Control Method | Pendent/Remote Control | |

| Protection Grade | IP44~65 | |

| The above are standard parameters, and customized solutions and designs are provided according to your actual needs. | ||

The product structure of electric hoist, the body is made of high-strength tensile shell or die-cast aluminum shell, and precision manufactured by thin-wall extrusion molding process, small in size, light in weight, and high in strength. The standard electric chain hoist has an independent gearbox system, the secondary coaxial transmission gear mechanism in the sealed gearbox, and a long-life oil bath lubrication system. The electric chain hoist powder metallurgy clutch is used as the overload protection device, and the brake adopts the disc type DC electromagnetic field brake. The braking torque is large, stable, rapid and low noise.

According to your special needs, we can provide many optional features, such as higher lifting height, different lifting speed, adapting different girder type and so on.

If you need the price or information about our hoists and cranes, please send an inquiry. We will reply you as soon as possible.