| Type | QD/QZ/QB/QY/QC/QDY/QL/QE |

| Capacity | 3 ton -800 ton |

| Span | 5m-60m |

| Applications | QD series crane is widely used for loading, unloading and handling of ordinary heavy objects, and can also be equipped with a variety of special spreaders for special operations. It is equipped with rainproof equipment when used in the open air. |

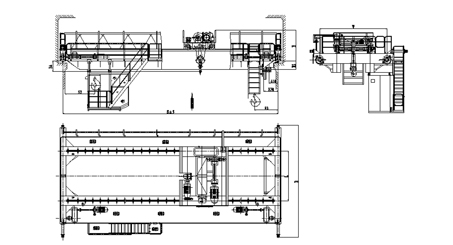

QD series double girder overhead cranes are currently widely used hoisting machinery. They can load, unload and transport materials and equipment in an intermittent and repetitive manner in a general operating environment. The load handling devices are divided into hooks, grabs, electromagnetic chucks, etc., to meet user needs to lift multiple types of materials.

| QD Series Double Girder Overhead Crane | ||

| Working Class | A5~A8 | |

| Capacity | t | 3~800 |

| Span | m | 5~60 |

| Lifting Height | m | 3~100 |

| Lifting Speed | m/min | 6~15.6,Single or Dual Speed |

| Trolley Travelling Speed | m/min | 20~44.6,Single or VFD |

| Crane Travelling Speed | m/min | 40~125,Single or VFD |

| Control Method | Ground or Cab Control | |

| Power Supply | 380V 50HZ 3 Phase or Customized | |

| Temperature | ℃ | -20~60 |

| Protection Grade | IP54~65 | |

| Optional Spreader | Hook, Grab, Electromagnet, Hanging Beam, C-hook, Lifting Tong. etc. | |

| The above are standard parameters, and customized solutions and designs are provided according to your actual needs. | ||

If you need the price or information about our hoists and cranes, please send an inquiry. We will reply you as soon as possible.