For electric single-girder cranes, its operation is inseparable from the application of any accessory. Take the crane busbar as an example: without its current transmission, it is difficult for the crane equipment to operate. Since the crane busbars used on different occasions are different, today, we will introduce the use and classification of crane busbars on electric single-girder cranes in detail.

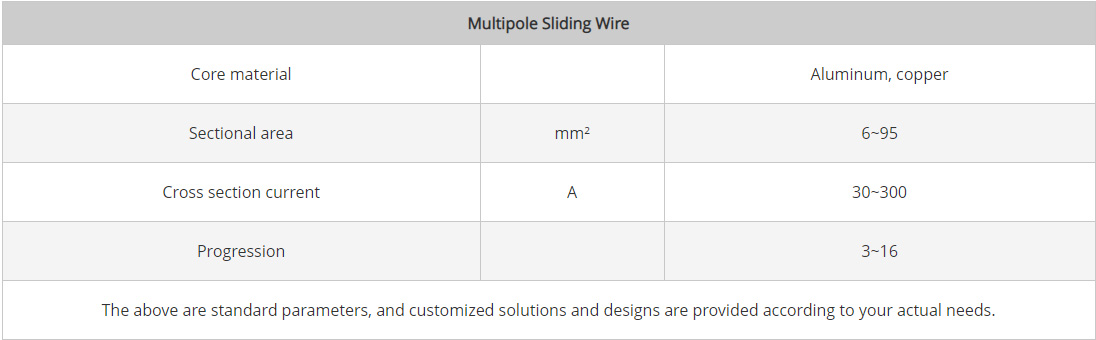

The power supply safety device of multipole sliding wire is for electric hoist, electric beam type, and bridge crane: automatic detection line and automatic production line of stacker, mechanical and electrical products, mobile electric tools, and other mobile conductive equipment, as well as fixed laying of bus duct in factories, mines, workshops, and offices.

The conduit safety type of multipole sliding wire is composed of high-strength engineering plastic or aluminum alloy protective shell, multi-stage conductive copper bar, collector, suspension, fixing, and other components. With the characteristics of compact design, stable performance, and safe use, it is widely used in low-current and high-frequency logistics automatic production lines and detection lines.

Datasheet:

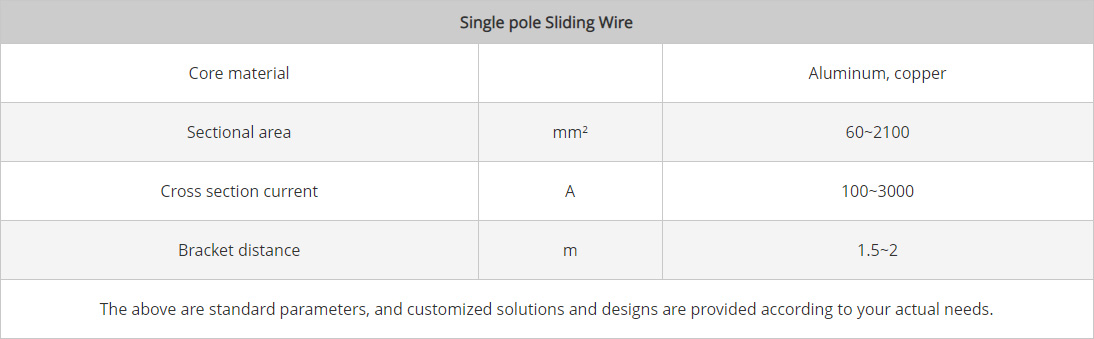

The single pole sliding wire is a power supply system that feeds the mobile mechanical equipment. The conductor is an aluminum alloy profile, and its outer sheath is the specific PVC material that can prevent rain, dust, snow, and electric shock.

Single pole sliding wire has a simple structure and convenient installation and maintenance, which is used widely in the power supply line of mobile equipment such as mine, metallurgy, chemical industry, machinery, wharf, freight yard, etc.

Datasheet:

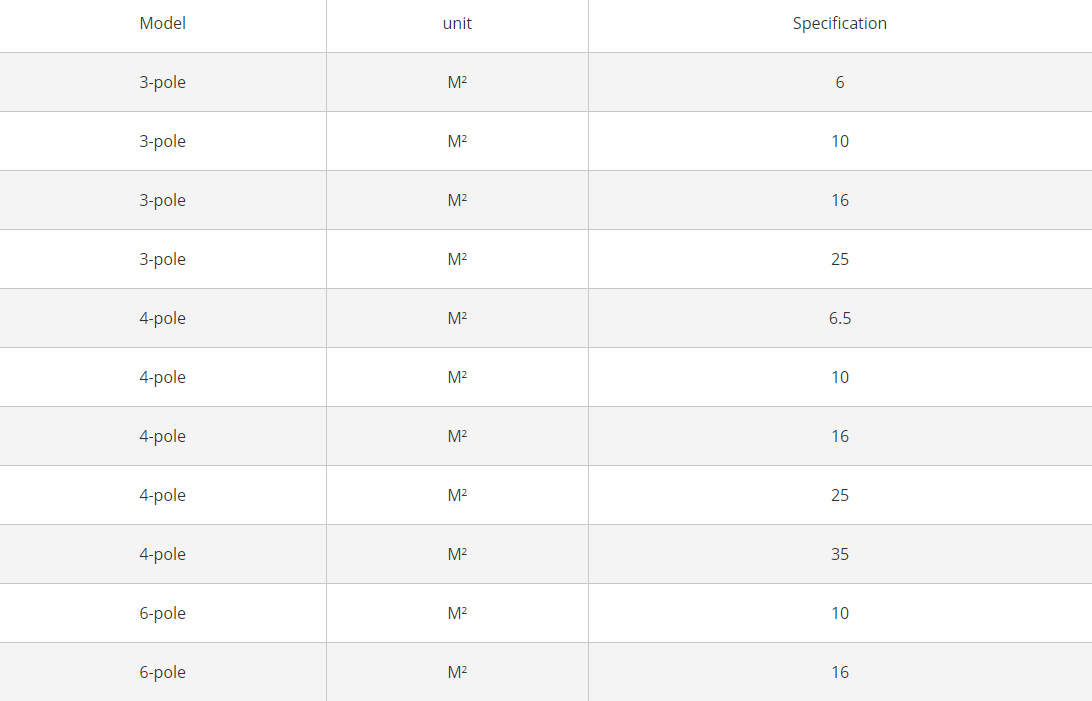

The jointless sliding wire is also called: jointless safety sliding wire, safety sliding wire, three in one safety sliding wire, four in one safety sliding wire, six in one safety sliding wire, three in one jointless sliding wire, four in one jointless sliding wire, six in one jointless sliding wire.

Seamless slide wire is produced by advanced technology. 3-pole, 4-pole, and 6-pole jointless sliding contact wires have the advantages of never power-off, power supply transmitted by oxygen-free copper, voltage drop force, double conductivity, good contact, convenient installation, not easy to wear, convenient replacement, more convenient transportation, not easy to cause damage to slid wire and prolong service life.

A seamless slide wire system consists of jointless slide wire, collector, and tension device.

Datasheet:

To a large extent, the sliding wires of the crane will supply power to the moving equipment, and this sliding wire product has two parts. One part is the sliding line guide rail (the fixed part), which connects to the power supply. The ordinary guide rail is usually connected by a single length of 4m/root or 6m/root.

The second part of the sliding wire of the crane, which is the current collector, actually refers to the sliding parts. It slides inside and, to a large extent, is in contact with the copper strip to get electricity, and the current collector is used to connect with the moving motor. In most cases, the crane sliding wire will work in dusty and humid environments. It may equip with dustproof sealing strips and hand protection (When the contact line is very close to the person, you should wear hand protection).

Before installing the crane sliding wire, fix the angle steel bracket according to the installation form selected by the user and according to the suspension distance of the trolley line, and put the required suspension seat on the trolley line every 6 meters at the installation site. And on one end of the joint sheath, and one aluminum joint is installed at one end. When installing the aluminum joint, it needs to note that only 1/2 of the aluminum guide rail can extend into the joint and is reserved for the other guide rail connection. After the above work is ready, hang the sliding contact wires one by one on the bracket to connect the whole line. Tighten the screws of each joint when connecting.

When the total length of the trolley line exceeds 200 meters, an expansion device should install. The expansion device can supply by the factory at any time.

When installing the sliding contact line of the curved crane, the suspension distance should shorten accordingly, and the specific size can be determined according to the site conditions.

When installing the conductor, install the conductor on the matching square tube, select the appropriate position to match the trolley wire, and fix it on the electrical equipment. It needs to note that the conductor and the trolley wire have good tracking performance and for good contact ability, the conductor and the sliding contact line should install in the same vertical and horizontal direction.

As a professional crane manufacturer, we can provide different kinds of cranes, hoists, and crane spare parts. If you have any inquiry of a crane busbar or other cranes, hoists, or crane spare parts, contact us at any time.