As the name suggests, the crane seamless busbar system is a complete middle without interface and is called the seamless busbar. Because there is no interface in the middle of the seamless busbar, the entire copper wire is overpowered, which reduces the power failure of the middle connection interface caused by shaking, and greatly improves the safety production and work efficiency. Therefore, the seamless crane busbar has become popular in the crane and mobile power supply machinery industry in recent years.

For the overhead crane, gantry crane, etc. generally, these cranes are used indoors, we will recommend a suitable busbar model, Seamless crane busbar is one model. When the cranes are delivered to the client site, some clients asked about how to install the busbar. The crane is a special machine, so we suggest that you can find a professional installation team to do the installation work.

Seamless busbar, the use of advanced technology production, 3 poles, 4 poles, 6 poles seamless busbar, with never power off, with oxygen-free copper transmission power, pressure drop force, conductivity times better, good contact, easy installation, not easy to wear, easy to replace, more convenient transportation, not easy to cause sliding contact line damage, extend service life.

Products with advanced technology, fine workmanship, and beautiful appearance, it is the ideal replacement for lifting industry system products, widely absorb the essence of science and technology, forge ahead, pioneering and innovative, products have formed a series, standardization, and can be designed and manufactured according to user requirements.

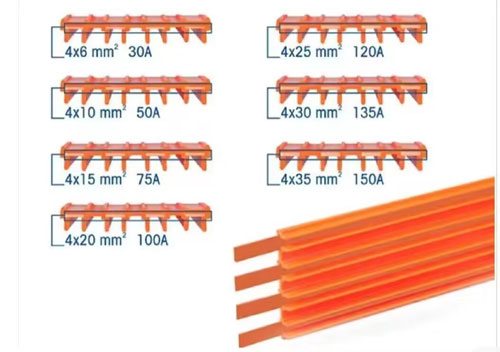

Now, I will introduce the normal seamless busbar model for you. As below pictures showed, the normal seamless busbar model, when we design the crane solution, we will choose the most suitable busbar model for you.

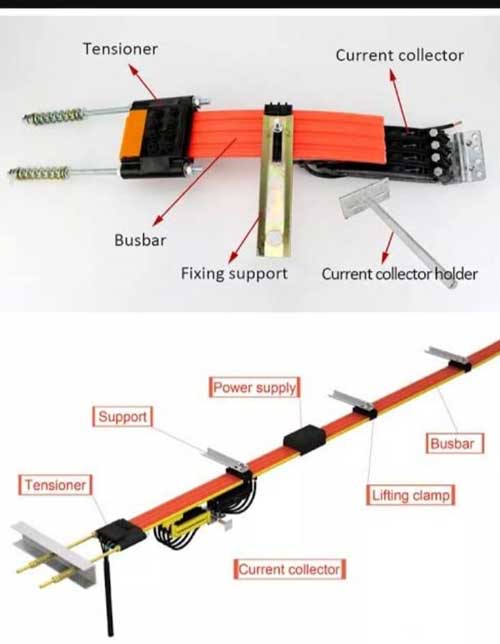

For the seamless busbar, the main part including: busbar, tensioner, elevator, junction box, collector, bracket. All these parts we will deliver to you together with the busbar.

For the crane busbar installation, please kindly following steps below:

If you only want to replace the busbar or want to purchase the busbar for your exist crane, we can also provide. But we need you to provide the total power of your crane and also the crane travelling length, and then we can recommend the most suitable busbar model and calculate the best price for you.