An electric hoist is a small and light lifting equipment driven by electricity. It is mainly used for vertical lifting, horizontal transportation, or precise lifting of various heavy goods. It realizes efficient and safe lifting operations through the combination of motor, reduction mechanism, wire rope/chain and other components, and is widely used in industry, construction, warehousing, logistics and other fields. Compared with manual hoists, it is more labor-saving, faster, and more accurate and is an important tool for modern lifting operations.

The electric hoist can be classified according to the lifting mechanism, installation mode, usage environment, control mode, etc. Different types of electric hoists are suitable for different scenes. The following are detailed categories and differences.

| Type | Wire rope hoist | Electric chain hoist |

| Lifting structure | Lifting by wire rope winding | Alloy chain lifting |

| Lifting capacity | 0.25 ~ 80 ton | 0.5 ~ 50 ton |

| Lifting height | 3 ~ 100m | 3~30m |

| Lifting Speed | 0.33~8 m/min, single or dual speed | 0.25~21 m/min, single or dual speed |

| Application | Heavy industry, construction, ports, etc | Precision assembly, mold installation, workshop maintenance, etc |

| Advantage | Large bearing capacity, fast speed, suitable for long distance lifting | Compact structure, accurate positioning, suitable for narrow Spaces |

| Disadvantage | The volume is large, and the wear of the wire rope should be checked regularly | Slow speed, not suitable for large tonnage |

| Main Difference | Bearer mode | |

Suggestion for choosing this type of electric hoist:

If you need a large tonnage electric hoist to lift goods for a long distance, wire rope hoist is suitable for your actual needs.

If you need an electric hoist to lift goods in small space operation and require precision control, electric chain hoist is suitable for your factory.

| Type | Fixed electric hoist | Electric hoist with trolley |

| Installation mode | Fixed to a bracket or cantilever | It can move along the I-beam |

| Movability | Not movable, only vertical lift | Can move horizontally and vertically |

| Application | Fixed point lifting (e.g. production line, warehouse) | Horizontal handling is required (e.g. workshop, logistics center) |

| Control mode | Button/pendant control | Button/pendant control plus electric trolley control |

| Advantage | Simple structure and low cost | High flexibility and wide space coverage |

| Disadvantage | Limited operating range | Rails need to be installed and the cost is high |

| Main difference | Movability | |

Suggestion for choosing this type of electric hoist:

If you require an electric hoist to lift goods on fixed position, the fixed type electric hoist is suitable for your warehouse.

If you require an electric hoist to move to lift goods, the electric hoist with trolley is suitable for your workshop.

| Type | Ordinary electric hoist | Explosion proof hoist | Anticorrosive electric hoist | Casting electric hoist/Metallurgical electric hoist |

| Application | General workshop, warehouse | Petroleum, chemical, coal (flammable and explosive) | Marine, food plant (moisture, corrosion) | Metallurgy industry, casting industry (high temperature) |

| Level of protection | IP54~IP55 | Ex dⅡBT4 (explosion-proof certification) | IP65 (waterproof and rust-proof) | High temperature motor (>60℃) |

| Material | Common iron | Explosion-proof motor + special housing | Stainless steel/galvanized material | Heat-resistant coating |

| Price | Lower | Higher (2-3 times higher than common) | Medium-high | Higher |

| Main difference | Level of protection | |||

Suggestion for choosing this type of electric hoist:

If your factory belongs to an ordinary workshop, the standard ordinary electric hoist can meet your needs.

If your operation space belongs to petroleum, chemical, coal, etc., you need to choose explosion proof hoists and must meet safety standards.

If your workshop belongs to seafood processing, food plant or is in coastal areas, the anticorrosive electric hoist is suitable.

If your factory belongs to metallurgy industry, casting industry under high temperature, the casting electric hoist/metallurgical electric hoist can meet your actual requirement.

| Type | Ordinary pendant control | Remote pendant control | Variable frequency control | Intelligent control |

| Control mode | Wired button box | Wireless remote control (10 ~ 100m) | Variable frequency speed regulation (accurate start and stop) | PLC/APP remote control |

| Application | regular operation | Long distance or high altitude operation | Precision lifting (e.g. glass, precision instruments) | Automated warehousing, smart factory |

| Advantage | Low cost, stable | Flexible operation and high security | Smooth operation, accurate positioning | Intelligent management system can be integrated |

| Disadvantage | Cable limited | Need to replace the battery | Higher price | Intelligent system is required |

| Application | General workshop | Large warehouses, construction sites, etc | Automotive assembly line, electronic equipment installation, etc | Intelligent logistics center, etc |

| Main difference | Control mode | |||

Suggestion for choosing this type of electric hoist:

If you regularly operate to lift goods in your warehouse, the electric hoist with wired pendant control can meet your needs.

If you operate to lift goods in a long distance or high altitude, the electric hoist with wireless remote control is the better selection for you.

If you need precision to lift materials in your workshop, the electric hoist with variable frequency control is suitable.

If your operation is in intelligent plants, the electric hoist with PLC/APP remote control is designed for you.

| Type | Single speed hoist | dual speed hoist | Low headroom hoist | Metallurgical hoist |

| Feature | Single speed | Fast/slow dual speed switch | Save headspace | High temperature resistance, metal splash resistance |

| Application | Ordinary lifting | Precision installation (e.g. equipment alignment) | Low-rise factory | Steel factory, casting workshop |

| Advantage | simple mechanism | Precise control | Maximize space utilization | Resistance to extreme environments |

| Model | CD type | MD type | Low headroom chain hoist | Metallurgical wire rope hoist |

| Main difference | special purpose | |||

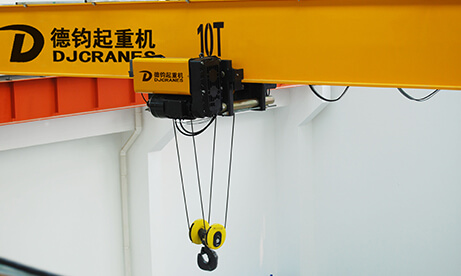

Wire rope electric hoist is a kind of electric lifting equipment with wire rope as the carrying part, which has the characteristics of large carrying capacity from 0.25 ton to 80 ton, high lifting height from 3m to 100m and fast running speed. Besides, we also offer custom designed service to your special requirements.

Learn more

Learn more

Learn more

Learn more

Learn more

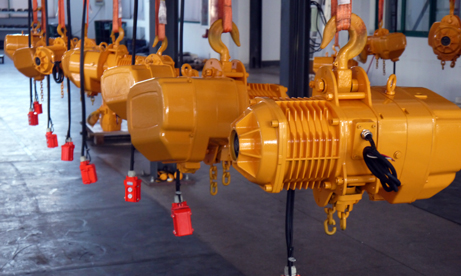

Electric chain hoist is a kind of lifting equipment driven by electricity, using high-strength chain as a bearing part, suitable for vertical lifting or horizontal lifting of heavy objects. It has the characteristics of compact structure, strong load capacity, flexible operation, etc., and is widely used in factory, warehouse, construction, ship maintenance and other occasions.

Learn more

Lear more

.jpg)

Learn more

Learn more

Learn more

Besides selling electric hoists to the above countries, our electric hoists are also sold in these countries: Albania, Algeria, Argentina, Azerbaijan, Egypt, Estonia, Australia, Pakistan, Paraguay, Panama, Brazil, Belize, Dominica, Russia, Ecuador, Philippine, Fiji, Finland, Congo, Columbia, Georgia, Guyana, Kazakhstan, Zimbabwe, Qatar, Croatia, Uzbekistan, Spain, Singapore, Italy, etc. You can touch with us for more details of performance about our electric hoists in more countries.

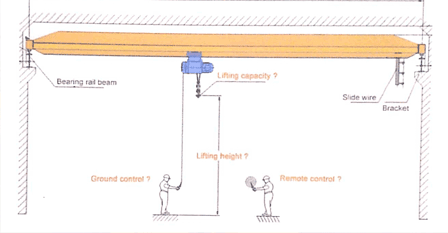

Electric hoists are customized products, not standard products. For providing the high cost-performance price of electric hoists according to your actual needs, we need to know these basic parameters below.

Henan Dejun Industry Co., Ltd, is a comprehensive industrial manufactuer with providing types of electric hoists, overhead cranes, gantry cranes, jib cranes, winches, etc. If you have any inquiries, please feel free to contact us.