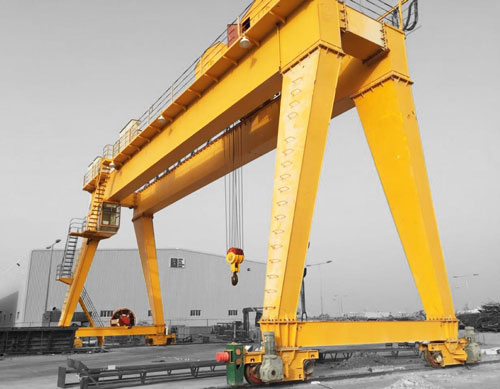

A double-girder gantry crane plays a crucial role in the world of heavy industry, logistics, and large-scale construction. Efficiency and safety are not just goals—they are imperatives in the modern industrial society. Whether you’re moving heavy machinery, handling shipping containers, or assembling massive structural components, you need crane equipment you can rely on. Dejun Cranes are designed to be the workhorse of your operation, lifting immense loads with ease and transforming your material handling processes.

Unlike a single-girder gantry crane, the double-girder gantry crane design is to provide superior strength, stability, and hook height. This makes it the ideal solution for the most challenging applications where capacity and precision are critical.

From the initial inquiry in November 2024 to the final deal in July 2025, Dejun Cranes customized two 30-ton (25+5) double-girder gantry cranes for their heavy-duty outdoor operation area, specifically designed for lifting large steel components. This project not only solved the client’s lifting challenges in harsh outdoor conditions but also demonstrated our professional strength in heavy lifting equipment and our deep understanding of the Middle East market.

Customer Background and Challenges

The client is from the rapidly developing United Arab Emirates. Their business involves large-scale steel structure processing, logistics warehousing or infrastructure construction. The client requires two high-performance double girder gantry cranes for outdoor storage yards, to frequently lift steel coils, steel beams or large steel components weighing up to 30 tons.

The core challenges of the client’s site:

Project timeline and key stages:

November 2024: Initial Inquiry and Demand Deepening

The client sent out a preliminary inquiry for two 30-ton double-girder gantry cranes. Our sales and technical teams promptly responded and, through multiple online meetings, gained a thorough understanding of the client’s specific working conditions, usage frequency, span, lifting height and other key parameters. We also provided initial gantry crane equipment selection suggestions.

December 2024–March 2025: Customization of technical solutions and quotations

During this period, the client visited the factory of Henan Dejun Industrial Co., Ltd. in person. Based on our further in-depth communication face by face, we submitted a detailed technical solution and quotation. The core of the solution targeted the client’s pain points and proposed the following customized designs:

April–June 2025: Technical Clarification and Contract Negotiation

The client conducted a thorough review of the plan and held multiple rounds of discussions on some technical details and business terms. We demonstrated great patience and professionalism, providing all necessary technical clarifications and similar project cases, and ultimately won the client’s trust.

July 2025: Contract Signing and Project Initiation

Both parties reached an agreement on all terms and successfully signed the purchase contract and made the deposit payment. The project then entered the production and manufacturing stage.

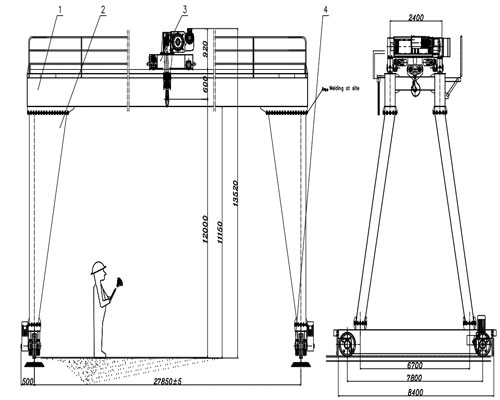

| Lifting Capacity | 25 + 5 tons |

| Span | 31.46m |

| Cantilever | 5.524m |

| Lifting Height | 20m |

| Power Supply | 380V 50Hz 3Phase |

| Working Class | A5 (ISO M5) |

| Standard | FEM2M |

| 25 Ton Trolley Lifting Speed | 0.32–3.2m/min (VFD) |

| 25 Ton Trolley Cross Travelling Speed | 2 – 20m/min (VFD) |

| 5 Ton Trolley Lifting Speed | 0.8 – 5m/min (VFD) |

| 5 Ton Trolley Cross Travelling Speed | 2 – 20m/min (VFD) |

| Long Travel Speed | 3 – 30m/min (VFD) |

| Protection Class | IP55 |

| Insulation Class | F class |

| Operating Temperature | 0℃ — +50℃ |

| Electrics Brand | Schneider |

What we offer to our customer is not just two gantry cranes, but a complete outdoor heavy lifting solution. The tailor-made anti-corrosion and structural design of this solution ensures the long service life and low failure rate of the gantry crane equipment in the outdoor environment of the United Arab Emirates; the smooth variable frequency control and large power lifting mechanism significantly improve the efficiency of steel piece lifting and shorten the operation cycle; the all-round safety protection devices provide the highest level of protection for operators, equipment and lifted objects; and the modular design and easily accessible maintenance points reduce the difficulty and cost of daily maintenance and later maintenance.

These two 30-ton double-girder gantry cranes play a crucial role in the production logistics of the customer’s factory, effectively enhancing their material turnover capacity, reducing operational risks, and providing solid hardware support for future business expansion.

Summary

Henan Dejun Industrial Co., Ltd. is an international enterprise specializing in the research, manufacturing, and service of high-end lifting machinery. With profound technical accumulation and precise grasp of different market demands worldwide, we are committed to providing every customer with the safest, most reliable and most efficient material handling solutions.