Introduction

As global environmental awareness grows, industrial construction faces increasing pressure to adopt eco-friendly practices. Steel structures have emerged as a cornerstone of green factory design, offering unparalleled advantages in sustainability, energy efficiency, and pollution reduction. China, as a global leader in steel production and technological innovation, now delivers high-quality steel solutions tailored to meet the demands of large-scale industrial facilities, aligning with the country’s national “dual-carbon” goals.

Environmental Advantages of Steel-Structure Factories

Dust & Waste Reduction: Unlike traditional materials (e.g., concrete, bricks), prefabricated steel components minimize on-site dust and construction waste by up to 70%, significantly improving air quality and worker health.

Recyclability: 90% of steel used in factories can be recycled without quality loss, reducing landfill dependency and enabling circular resource utilization.

Steel production processes in China now achieve 40% lower CO₂ emissions compared to 2010 through EAF (Electric Arc Furnace) technology and renewable energy integration.

Modular designs reduce material waste by 25%, with precise CNC cutting optimizing resource efficiency.

Energy-Efficient Design Strategies for Industrial Steel Structure Buildings

High-Temperature Workshops: Ceramic fiber-insulated panels and thermal-reflective coatings are applied to steel frames in foundries or chemical plants, reducing heat transfer by 60% and cutting HVAC energy consumption.

Cold Storage Facilities: Vacuum-insulated sandwich panels maintain stable temperatures, achieving 30% energy savings versus conventional designs.

Acoustic Optimization: Perforated steel panels with mineral wool infill reduce equipment noise by 50 dB, critical for machinery-intensive plants.

Glare Management: Low-emissivity (Low-E) coated steel cladding minimizes light reflection, addressing urban light pollution regulations.

Steel roof trusses support photovoltaic arrays with 2x higher load capacity than concrete, enabling factories to achieve 40% solar energy self-sufficiency.

Rainwater harvesting systems embedded in steel frameworks reduce municipal water usage by 35%.

Economic & Operational Benefits for Industrial Steel Structure Buildings

Prefabricated steel components enable 50% faster assembly than traditional methods, critical for industries requiring rapid production line deployment (e.g., EV battery plants).

Steel’s high strength-to-weight ratio ensures seismic resilience (up to 9 Richter scale), while hot-dip galvanizing extends structural lifespan to 50+ years even in coastal corrosive environments.

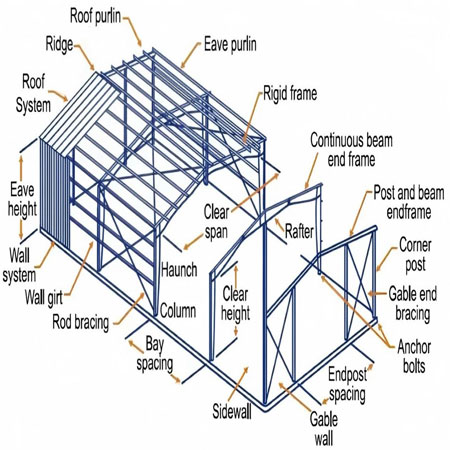

Clear-span steel structures (up to 100m unsupported) allow flexible floor plan reconfiguration to accommodate evolving production needs.

Conclusion

Steel structure factories represent the future of sustainable industrial development. By combining China’s advanced steel manufacturing capabilities with intelligent green technologies, these buildings achieve:

As global industries accelerate decarbonization efforts, steel-framed factories will remain pivotal in achieving ESG goals while maintaining operational competitiveness. Besides providing overhead cranes and gantry cranes, Henan Dejun Industrial Co., Ltd. also provides steel structures. If you have any inquiries, please feel free to contact us.