Crane rail (also known as crane track) is a specialized rail system designed to provide a running path for cranes (such as overhead cranes, gantry cranes, etc.), ensuring that cranes can move smoothly and safely. Below is an introduction to the QU series of crane rail.

QU Series Crane Rail Standard System

Chinese standard: GB/T 11264-2012 (replacing the old YB/T 5055)

International benchmarking: ISO 1834:2018, ISO 6303:1980

European standard: DIN 536 (Series A)

American Standard: ASCE/AAR Standard

Objective: JIS E1101 (CR series)

International Standard Comparison of QU Crane Rail

| China | Europe | United States | Japan |

| QU70 | A65 | ASCE25 | CR60 |

| QU100 | A100 | ASCE60 | CR80 |

| QU120 | A120 | ASCE85 | CR100 |

Comparison of QU Model Crane Rail Parameters

| Model | Section dimensions (mm) | Theoretical weight (kg/m) | Applicable lifting capacity (ton) | Head width (mm) | Waist thickness (mm) |

| QU70 | 70*70 | 33.3 | Less or equal 10t | 50 | 25 |

| QU80 | 80*80 | 43.5 | 10-20t | 60 | 28 |

| QU100 | 100*100 | 68.2 | 20-50t | 70 | 32 |

| QU120 | 120*120 | 98.3 | 50-100t | 80 | 38 |

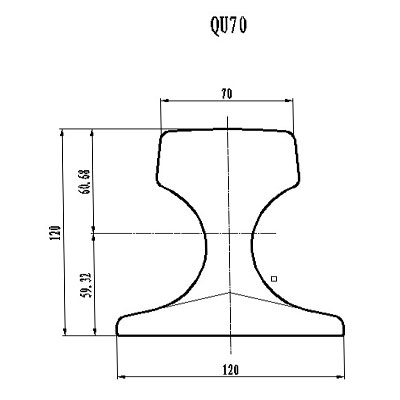

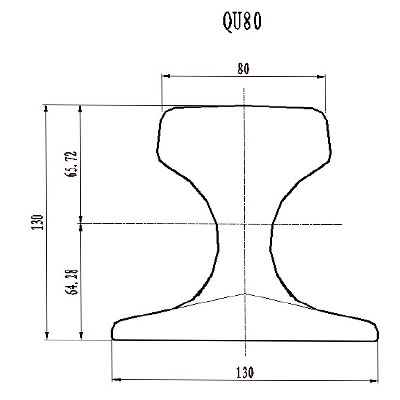

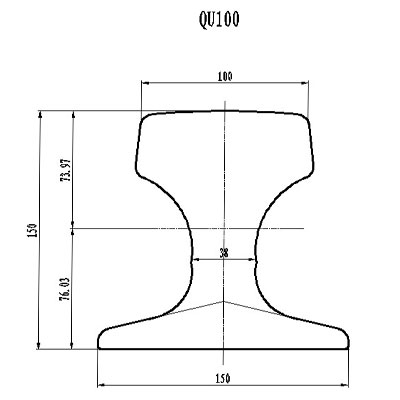

Part of QU Crane Rail Drawings

Key Structural Features of QU Crane Rail

Material Technical Requirements of QU Crane Rail

1. Chemical Composition

2. Mechanical properties

Installation Technical Specifications of QU Crane Rail

1. Basic Requirements

2. Installation tolerance

Special Processing Techniques of QU Crane Rail

Maintenance Inspection Standards of QU Crane Rail

1. Wear limit

2. Inspection cycle

Conclusion

In conclusion, the selection of the crane rail is an indispensable part of a perfect crane solution. An appropriate rail not only helps to save costs but also protects the wheels and extends their service life. So, if you encounter any questions regarding the selection of crane rails, please directly contact the relevant factories to seek their advice. Henan Dejun Industry Co., Ltd has more than 30 years in crane filed, we have enough confidence to provide the top quality crane and suitable solution, any questions, contact us freely, our team always here!