Portable gantry cranes (commonly known as “gantry cranes”) are mainly used in open-air sites, warehouses, or temporary construction sites. During installation, safety regulations must be strictly followed to ensure structural stability and operational reliability. The following are the key installation steps and precautions.

1. Site inspection

Confirm that the ground is level and compacted. The bearing capacity should meet the sum of the self-weight of the portable gantry crane and the maximum load (generally, the bearing capacity of the foundation should be ≥10t/m²).

2. Equipment acceptance

Check that the main beam, outriggers, electric hoists, and other components have no deformation, rust, or welding defects. Check whether the electrical components (motors, limit switches, cables) meet the dust and water resistance grade (such as IP54).

3. Tools and personnel

Prepare tools such as a crane (or forklift), a level, a torque wrench, and a theodolite. Installers must be certified to work (such as the qualification certificate for hoisting machinery installation).

1. The outriggers are installed with the lower crossbeam

Leg verticality: Calibrated with a theodolite, with a deviation of ≤1/1000 (for example, the allowable deviation at a height of 10m is ≤ 10 mm).

Bolt tightening: High-strength bolts should be tightened in stages according to the designed torque (for example, the torque of an M20 bolt is approximately 400 N ·m).

2. Main beam hoisting

Selection of lifting points: Special lifting lugs should be used for the hoisting of the main beam to avoid direct compression of the beam body by the steel wire rope.

Levelness adjustment: The mid-span camber of the main beam should be (0.9-1.4) S/1000 (S is the span), for example, for a 20m span, the camber should be 20-28 mm.

3. Electric hoists and electrical system installation

Alignment of hoist tracks: The gap between I-beam track joints is ≤2 mm, and the height difference is ≤1 mm.

Limit switch test: The upper limit of lifting and the limit of the walking terminal need to be manually triggered for verification.

Grounding protection: Metal structures must be reliably grounded (grounding resistance ≤4 Ω).

4. Trial operation and debugging

The electric hoist can move throughout the entire journey without any jamming and the chain has no kinking. The large vehicle/small vehicle operates without deviation (offset ≤S/1000, for example, a 20m span is allowed to be ≤20 mm).

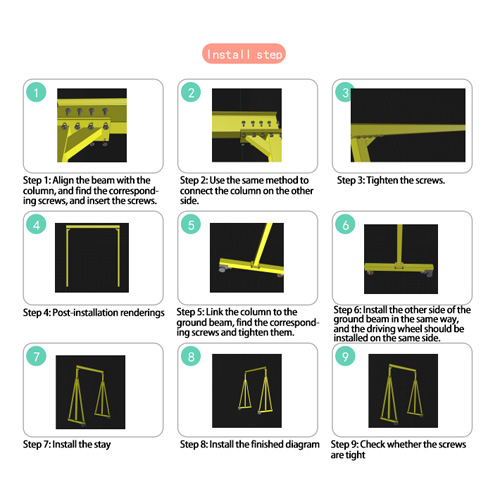

5. Brief summary of nine steps

Step 1: Align the beam with the column, and find the corresponding screws, and insert the screws.

Step 2: Use the same method to connect the column on the other side.

Step 3: Tighten the screws.

Step 4: Post-installation renderings

Step 5: Link the column to the ground beam, find the corresponding screws and tighten them.

Step 6: Install the other side of the ground beam in the same way, and the driving wheel should be installed on the same side.

Step 7: Install the stay

Step 8: Install the finished diagram

Step 9: Check whether the screws are tight

1. Windproof and anti-overturning

When used outdoors, windproof cables or counterweights (such as sandbags) should be added. Operations should be halted when the wind speeds reaches or exceeds level 6 (12m/s). Do not use on slopes (with an inclination greater than 3°) or soft ground.

2. Load limitation

Overloading is strictly prohibited (the rated load is marked on the nameplate). The center of gravity of the lifted object must be centered. Oblique pulling or colliding with the outriggers is strictly prohibited.

3. Personnel safety

When operating, it is strictly prohibited to stand under the lifted object or on the moving path of the portable gantry crane.

1. Check after use

Clean the chain/wire rope and apply anti-rust grease. Check if the bolts are loose and if the wheel brakes are sensitive.

2. Storage requirements

After disassembly, store in a dry environment to prevent the main beam from being deformed under pressure. The electric hoist needs to be disconnected from the power supply and the battery should be removed with the remote control.

Q: How heavy can a portable gantry crane lift?

A: Common models have a load capacity of 0.5T to 5T, with the specific capacity subject to the nameplate. Overloading may cause structural deformation or collapse!

Q: What should I do if the wheels of a portable gantry crane slip?

A: Check if the ground is level and if the brakes are locked. Replace the rubber wheels or install anti-slip pads when necessary.

Q: Is the shaking of the main beam of the portable gantry crane normal?

A: Slight shaking is normal, but if the amplitude is too large (> 50 mm/3 m span), it is necessary to check the verticality of the outrigger or reinforce the connection points.

Note: there may be detailed differences among portable gantry crane of different brands. Please refer to the manufacturer’s manual for accuracy. If the problem cannot be solved by yourself, please contact after-sales service!